By utilizing our pipe fabrication shop, S. P. McCarl & Company, Inc. reduces installation costs while ensuring a proactively managed construction schedule. The controlled work environment allows our skilled crafts persons to produce quality pipe spools before shipping them to the job site.

S. P. McCarl & Company, Inc.'s pipe fabrication shop produces: pipe spools, piping skids, tanks, pressure vessels, elbows,…any application involving piping. Our ASME code shop provides piping components for countless customers and industries. Our pipe fabrication client base includes industrial and heavy commercial facilities with a recent focus on the Marcellus Shale industry. We have the pipe fabrication expertise to fit your needs.

Our Pipe Fabrication Expertise includes:

| Carbon Steel Piping | ASME Code Welding |

| Stainless Steel Piping | Power Piping |

| Aluminum Piping | High Pressure Steam Piping |

| Special Alloy Piping | Double Wall Containment Piping |

| Copper Piping | Pipe Bending |

| PVC Piping |

Pipe Fabrication Capabilities

S. P. McCarl & Company, Inc.'s pipe fabrication supports large or small projects:

- – Small bore pipe & tube up through 36 inches in diameter

- – All schedules

Welding

- Procedure Specifications:

- Jointly developed with the NCPWB and AWS to ASME and API Requirements

Processes:

- SMAW Shielded Metal Arc Welding

- GTAW Gas Tungsten Arc Welding

- GMAQ Gas Metal Arc Welding

- Uphill Welding

- Downhill Welding

Materials:

- Aluminum

- Carbon Steel

- Chromium Molybdenum

- Copper

- PVC

- Special Alloy

- Stainless Steel

Roll Grooving

- Victaulic fully automated shop machine

- Carbon steel schedule 40, range of 2″-36″

- Copper range of 2″-6″

- Stainless steel schedules 5 & 10, range of 2″-36″

- PVC plastic schedule, range of 2″-36″

Bending

- 1/2″ to 3″ through schedule 80

Quality Assurance Program

- API 1104 Certified

- ASME Certified

- QA/QC Manual

- Quality Control System

- UA Weld Certified

Miscellaneous

- Hole punching – 1/8″ hole through 1-1/8″

- Non-destructive testing (ultrasonic, x-ray, etc.)

- Hydrostatic testing to 10,000 psi

- Weld join stress relieving

- Blasting & Painting

- 3-D CAD drafting, including BIM capabilities

- On screentake-off estimating software

- 11,000 SF

Pipe Fabrication Shop

Our 11,000 square foot facility has the ability to handle pipe & tube up to 36″ diameter in all schedules. As a result of our vision for continued growth, we are planning a significant shop floor expansion in the near future.

For pipe fabrication delivered to external customers, shop personnel follow detailed quality control procedures specific to the customer’s needs. On time delivery is critical and our team understands how important it is to our customers. We provide quick turnaround and responsiveness while always focusing on safety and quality.

Our controlled work environment provides efficient production, quality assurance/quality control and safety. Whether it’s a small commercial fabrication project or a large industrial ASME code welding project, our shop fabricates to our customers’ specific needs. All welds are completed per ASME weld procedures.

Our highly trained welders work with carbon steel, stainless steel, aluminum, and specialty alloys to name a few.

To support our internal field installation projects, our Preconstruction Department assists project managers to plan each project’s specific needs. This detailed planning process yields increased efficiency and quality. The team determines what piping to fabricate in the shop versus the field. After shop fabrication, piping components are delivered to the job site to be assembled and installed.

Pipe Fabrication – Project Portfolio

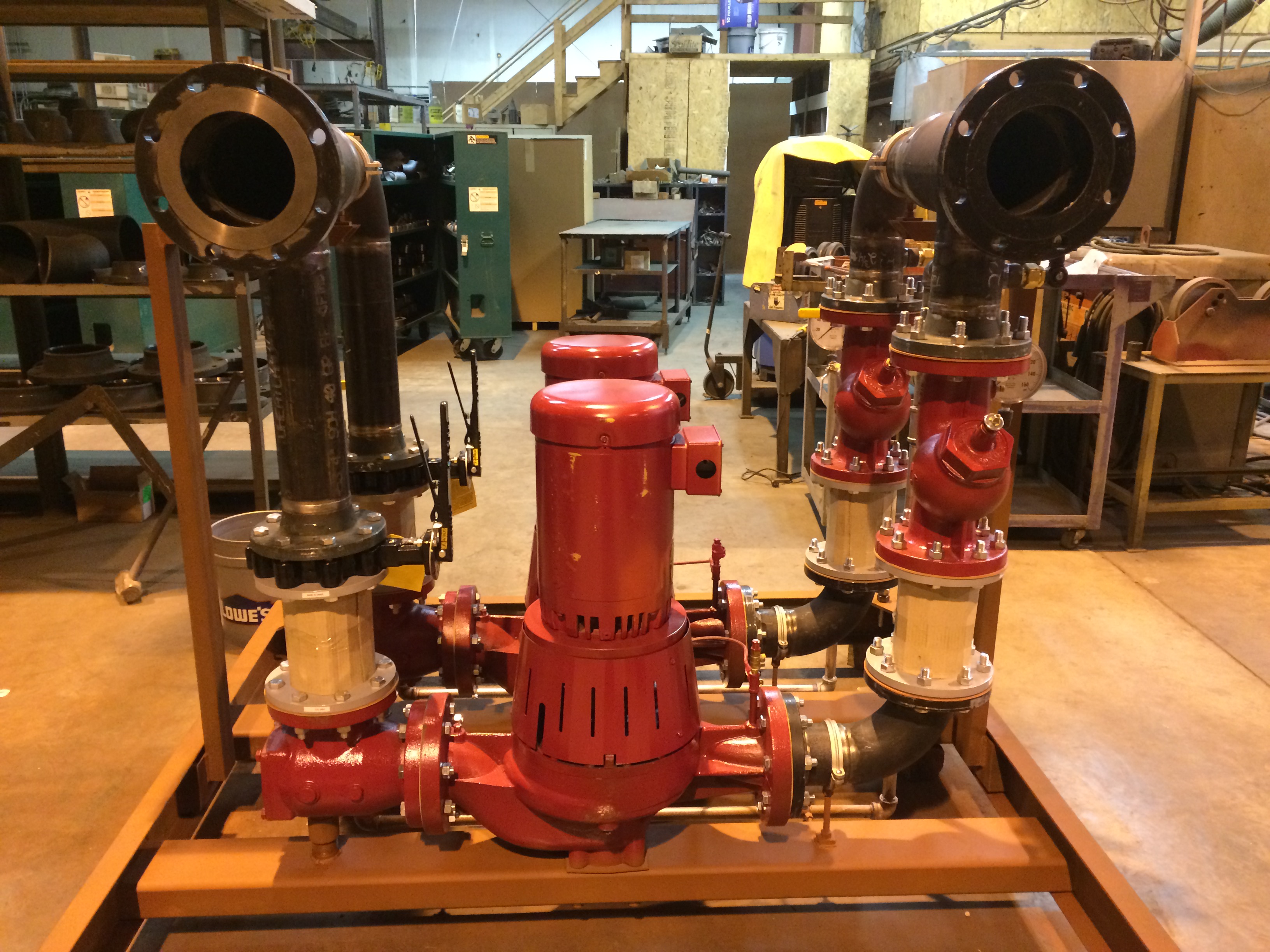

Our pipe fabrication shop can provide many custom fabrications. If you have any application involving piping, we will be able to assist you. A sample of some of the projects we have recently been involved with include:

| Welded pipe spools | Pipe skids |

| Threaded pipe spools | Non-ASME & ASME rated tanks |

| Grooved pipe spools | Non-ASME & ASME rated pressure vessels |

| Long radius elbows | Custom Fabrications |